The main movement and feed movement of X6132 universal milling machine are controlled by the hole plate speed change control mechanism.The following we take the main speed control mechanism as an example to explain its working principle.

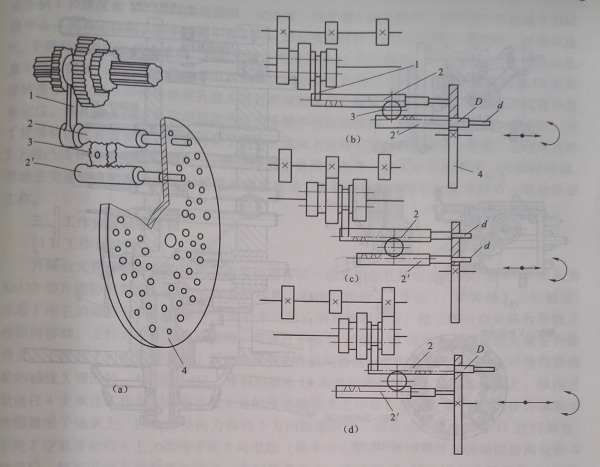

As shown in the figure is the use of hole plate speed control mechanism control triple slip gear schematic.Milling machine hole plate speed control mechanism mainly by the hole plate 4,the rack shaft 2 and 2 ',gear 3 and fork 1 composition.

The hole plate 4 is divided into several groups with different diameters, and each circumference is divided into 18 equal parts.According to the requirements of the gears at different positions during the gear change, the 18 positions are divided into three states: drilling big hole, drilling small hole or no drilling. The rack shafts 2 and 2'are machined with two rows of shoulder diameters of D and d respectively. The shoulder diameter of the d can pass through the holes on the orifice, and the shoulder diameter of D can pass through the big holes on the hole plate. Speed change, the first plate to the right shift, so that it back off the rack axis, and then according to the requirements of speed change, turn the disc to a certain angle, then make the hole plate left shift reset. When the hole plate is reset, the sliding gear can obtain three different positions through the big holes, the small holes or the non holes of the hole plate, so as to achieve the purpose of the speed change of the milling machine.Three working states are:

①The position of the corresponding rack shaft 2 on the hole plate is without hole, and the position corresponding to the rack shaft 2'is a big hole, and when the hole plate is reset, the left and top rack shaft 2 is pushed, and the triple sliding gear is pushed to the left position by the shifting fork. The rack shaft 2'moves right under the combined action of the rack shaft 2 and the pinion 3, and the shoulder D passes through the large hole on the hole plate;②The two holes are small holes, the small shoulder D of the rack shaft passes through the small holes on the hole plate, and the two rack shafts are in the middle position, so that the sliding gear is in the middle position by shifting the fork;③The hole plate corresponding to the rack shaft 2 position for large holes corresponding to the rack shaft 2'position without holes, the hole plate top rack shaft 2' left, and 3 to 2 through the gear rack shaft shoulder through hole right, and the gear is in the right place.

The structure of the main control mechanism is shown in the figure. It is an independent component mounted on the left side of the bed column of the metal mill machine and is operated by the handle 1 and the speed plate 10 for variable speed operation.When changing the rotational speed,the handle 1 is pulled out, the handle 1 by a pin 2 for rotation center, disengaged from the positioning pin 3 on the handle groove position; then counterclockwise rotation of the handle 1 is about 250 degrees, the steering wheel 9, and the flat key gear sleeve 4 to rotate, and then by the mobile rack gear 5 makes axis 11 to the right, the fork 12 shifts 8 hole plate moves to the right, the hole plate 8 from each rack shaft, to prepare for the 8 hole plate translocation; rotating speed of disc 10 to the desired speed position by a pair of bevel gears to 8 hole disc turns corresponding angle; finally, the handle 1 push back to the original position and re positioning, then move to the left and 8 hole disc drive each rack shaft for the corresponding displacement, speed of transformation.When changing speed, in order to make the sliding gear meshing position change in easy meshing, milling machine is provided with a main motor instantaneous impulse device, it uses bump 6 of gear 5 press the micro switch 7 is switched on, with the main motor power, the main motor to achieve a momentary impulse, drive the transmission gear of the main gear box to rotate at a slow speed, sliding gear can be smoothly moved to another position of engagement work.

The above is the introduction of the milling machine speed mechanism.